Another wondrous post from Jane Cooper telling the story from sheep to sweater of one very special garment!

I’ve spent the entire month wearing just one sweater. It’s been a fun way to celebrate Wovember but also a way to fully test the properties of a new knitting yarn. I’d like to introduce Orkney Wool Pure Texel Yarn.

It’s a yarn that I designed and had spun and dyed for me by Natural Fibre Company. The whole experience has been fascinating and, as Wovember comes to an end, I’m delighted to report that the yarn has exceeded my hopes and expectations.

Soon after moving to Orkney I noticed that the fleece up here seemed to be thicker, with finer fibres, compared to the same breeds I was familiar with from England. Possibly the result of all the rain and strong winds the sheep have to endure outside. Orkney has the climate and conditions to grow grass and so top quality grass-fed beef and lamb. While we cherish our unique North Ronaldsay sheep, the farming industry uses commercial pure and cross breeds.

When I started knitting over 50 years ago it was easy to buy British wool yarn that would last for decades. This is my husband’s sweater, knitted by his aunt in the early 1970’s and still worn regularly.

To create a yarn with similar qualities I selected the finest shearling fleeces from the pure breed Texel flocks at Veltigar Farm as they were being shorn and then started sampling. The wonderful mini-mill on North Ronaldsay is working to full capacity with North Ronaldsay wool and a little extra native breed wool, so I couldn’t go there. Instead I chose Natural Fibre Company to spin the yarn because I was familiar with the high quality of their yarns and their expertise with wool from different breeds of sheep.

I then hand-spun and sent down the woollen and worsted-spun samples, plus knitted samples, to test how different yarns worked for textured knitting and then the discussions started. Texel is a very versatile wool with a lot of natural loft so we had a number of options. In the end we settled on a woollen spun yarn with an extra combing in the preparation to increase the ‘soft’ feel of the final yarn. Every extra process adds to the cost of producing the yarn, but I think we got the balance about right. I really enjoyed the experience and challenge of working with the staff at NFC to design this yarn.

My objective was to create a knitting yarn that would be soft enough for any purpose, be durable, give good definition to texture and cables, create a firm fabric that retained elasticity, be resistant to pilling and be enjoyable to knit. If I’m spending tens of hours, or more, knitting a sweater I want to enjoy the knitting process and to still have the sweater looking good after many years of wear.

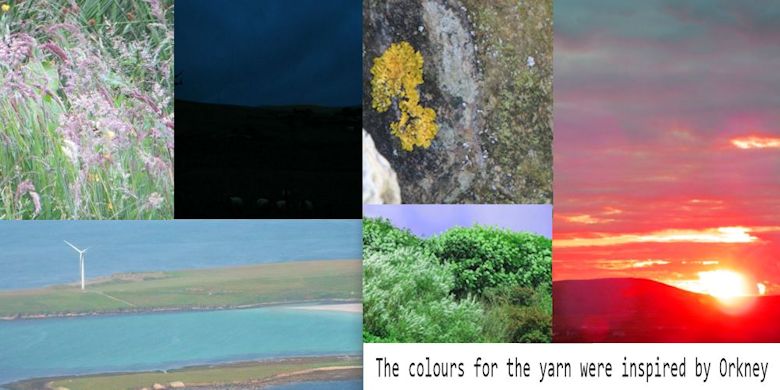

I also wanted the yarn to be in solid colours but with a ‘natural’ look about the yarn. A black Texel sheep in the flock provided the dark fleece that, when blended with the white fleeces, gives that special ‘wool’ look to the yarn. The colours were inspired by Orkney itself.

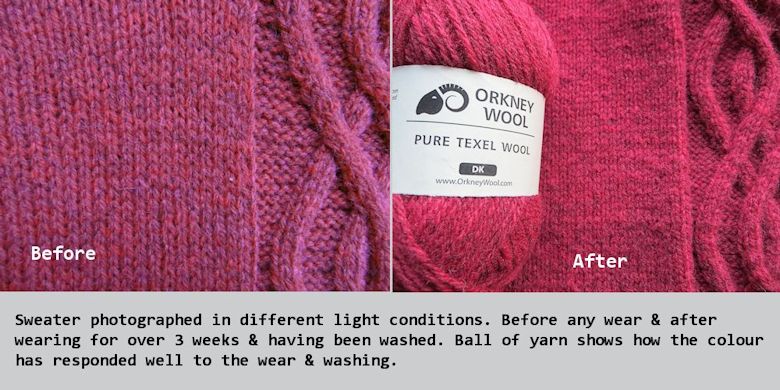

Yes, I did very much enjoy knitting the sweater. Natural Fibre Company certainly delivered a yarn that was easy to handle and didn’t have any issues with splitting or other nasties. I chose a design that had cables to test stitch definition and a neckline that would test the firmness and elasticity of the yarn as it was taken on and off – I don’t mollycoddle my sweaters as I pull them off at the end of a hard day working on the farm! If this yarn didn’t retain it’s elasticity and durability the sweater would be falling off my shoulders by the end of the month.

I wore a coat over the sweater for dirtier jobs on the farm, although I did manage this week to cover one cuff with raddle while applying it to Fraser the Gotland ram. The raddle transfers from the ram’s chest to the ewe’s rear end so you can see which ewes have been tupped. Fortunately I discovered that Eucalan will remove raddle. I took the opportunity to wash the sweater for the first time – another triumph!

Before this I’d just been sponging off obvious dirt and marks and hanging up the sweater outside for an hour or so if I’d been working up a sweat while wearing it. Wool has such amazing qualities that this is all that is needed on a regular basis, even when one sweater is being worn continuously.

After washing the sweater I did remove the bits and pills, photographing what I removed and what the sweater looked like with them on.

Considering how many hours I’ve been wearing this sweater for some pretty hard work as well as more relaxed times around the house, the pilling was much less than I’d dared to hope. This bodes well for the sweater looking good 20 years down the line since the yarn is obviously extremely durable.

My friends and neighbours have been very polite this month and not commented too much on the lack of variety in my choice of clothes. My knitting friends have been very understanding and interested about the experiment. I’m pleased the design of the sweater meant I could dress it up as well as dress it down. When in a warm room I just removed all the layers beneath the sweater and enjoyed the natural temperature regulation of wool and the fact that this yarn really was soft enough to have nothing on underneath it.

What started as a project to try and increase the price Orkney farmers could get for their best quality fleeces (the final cost of the yarn includes the farmer getting more than BWMB could have paid) has resulted in a yarn that I absolutely love. This year there is only a small amount. If it sells well then I hope to buy larger quantities of fleece next year and see if I can get any farmers interested in producing their own yarn from their fleeces, since that will give them the highest return for their fleece.

It has also been a very special way to enjoy Wovember and I’m still enjoying wearing the sweater. It won’t be consigned to the back of the wardrobe on 1 December!

What a fantastic story of wool grown on a farm and then road-tested on a farm; I love that this sweater has kept you warm during your own work of growing wool and your practical description of testing the new yarn you have made is really interesting. Hurrah for good strong wool!